Optimization

Client is UK’s leading manufacturer and distributor of oils and fats. with annual turnover of ~350 million USD. Imports, packs and distributes a wide array of food products to manufacturers, retailers and wholesalers throughout the UK and rest of the world.

Focus of the deployment : 500 SKUs (Repacked), 500 SKUs (Manufactured), 40 Suppliers across the world, 3 Manufacturing plants in UK, 2 Packaging centers in UK, 2 Distribution centers in UK

Business Problem

An ERP backend was in place. Most of the transactions were automated.The entire replenishment planning was being done manually using spreadsheets and home grown tools. Forecasting was being done using judgment and 3 months moving average at the retailer level. Inventory targets were set as DSI based on trial and error. Promotions for Ramadan and Diwali were based on forecasts from retailers. Procurement planning was based on spreadsheet based planning. It was done without considering any constraints and costs other than procurement cost

Project Objective

Automate and optimize the entire production and replenishment planning process for their entire operation and update the backend ERP with the optimized plans.

Solutions Deployed

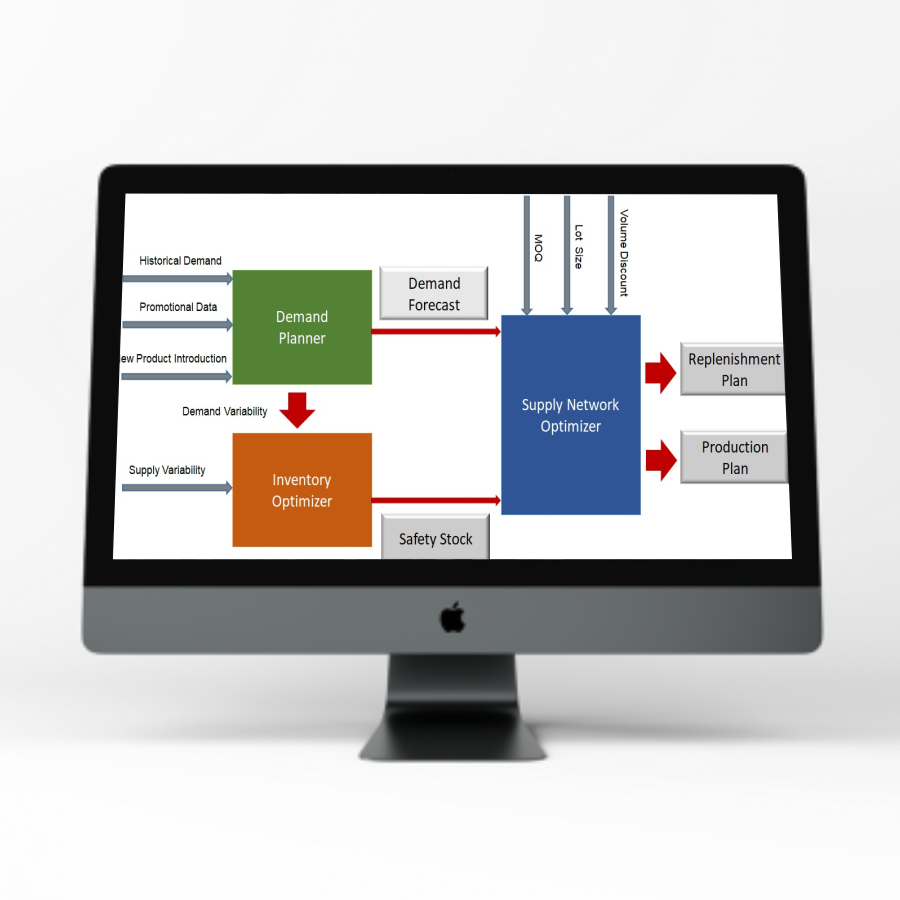

- Demand Planner

- Inventory Optimizer

- Supply Network Optimizer

Features

- Forecasting the demand using advanced statistical models and at an aggregated level

- Safety stock calculation at distribution centers based on the lead time and demand variability

- Procurement planning based on the forecasted demand, safety stock, minimum order quantity, lot size, fixed and variable transport cost, transportation capacity, procurement price, volume discounts, procurement and transportation lead times

- Production planning based on production and packaging capacities, BOM and Routing